¶ AMCU / BMCU / CMCU ......

The AMCU is a first generation system, and the project has been discontinued and abandoned.

AMCU Page1

AMCU Page2

The BMCU is the author's second-generation system, and the author's official development actions will gradually shift to the CMCU once the BMCU-C version has been stabilised.

The CMCU is in the early stages of development by the authors and their team. The CMCU is characterised by closed components similar to the AMS system, and the extruder mechanism will be integrated into a closed dryer box, but with a significant increase in the corresponding DIY cost.

¶ New BMCU naming convention

The authors @4061N have renamed the version iterations of the BMCUs as follows.

- BMCU-A : Version with 130 motors and Photoelectric sensors.

- BMCU-B : Version with 370 motors and Photoelectric sensors.

- BMCU-C : Version with 370 motors and Hall sensors.

- BMCU-D :BMCU-A integrated with B1 rewind unit. (Updated 25/05/2025)

✅ The Mainboard can be used universally across all versions.

⚠️ The BMCU-C requires a new sub-board with Hall sensor.

⚠️ The BMCU-D will use the old sub-board (with two photoelectric sensors) and the B1 rewind unit motherboard.

¶ Current branches of BMCUs

¶ Branches of the main structure of BMCU

BMCU

│

├── BMCU-A : 130 Motor/Photoelectric sensors

│ └── Many 130 Improved version ( Adjustable photoelectric block design, triangular clutch with spring, etc.)

│ └── 130 Steel ball version

│ └── 180 version

│

├── BMCU-B : 370 Motor/Photoelectric sensors

│ ├── 370 Original version v2.5

│ ├── 370 Steel ball version v3.14

│ └── 370X Microswitch version by @XC (Different sub-board!)

│

├── BMCU-C : 370 Motor/Hall Sensor

│ └── Two-Microswitch version by @XC and @ABin (Different sub-board!)

│

│

├── BMCU-D : BMCU-A integrated with B1 rewind unit. (Updated 25/05/2025)

│ └── Very early alpha test.

│

└── CMCU in the future

¶ Branches of the PCB of BMCU

BMCU

│

├── Mainboard

│ ├── Default version

│ ├── Front Type-C version (replace the original pin location with Type-C)

│ ├── Side Type-C version by @XC

│ └── Minor security patch version (small update with enhanced safety)

│

└── Sub-board

├── V1 Photoelectric sensors

│ └── Micro Switch version by @XC

└── V2 Hall sensors

└── Two-Microswitch version by @XC and @ABin

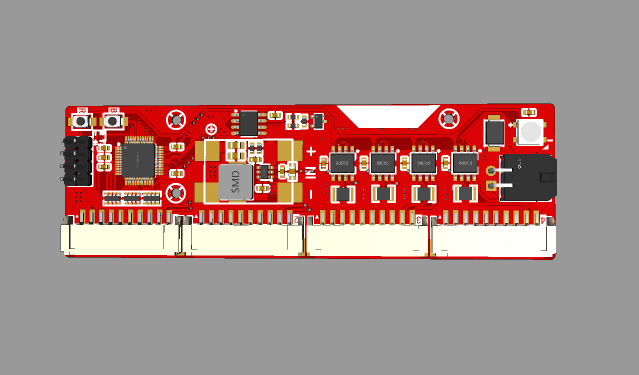

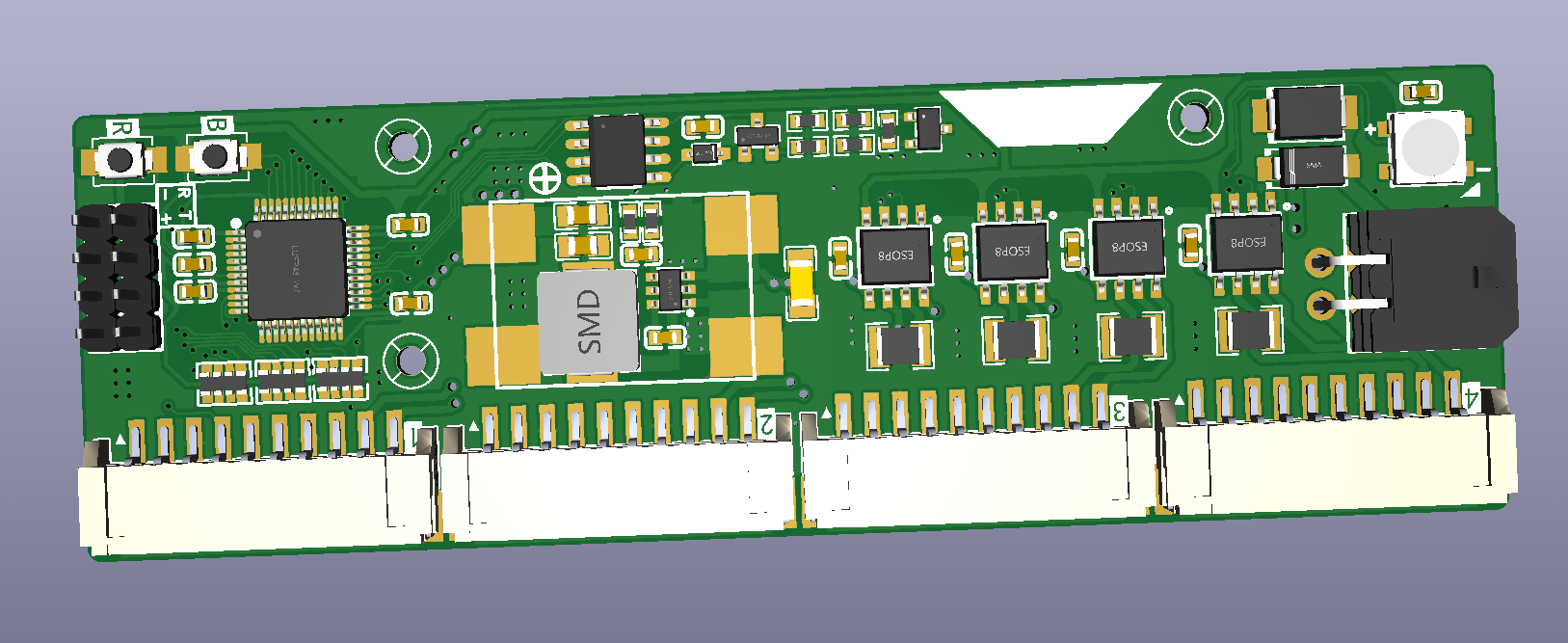

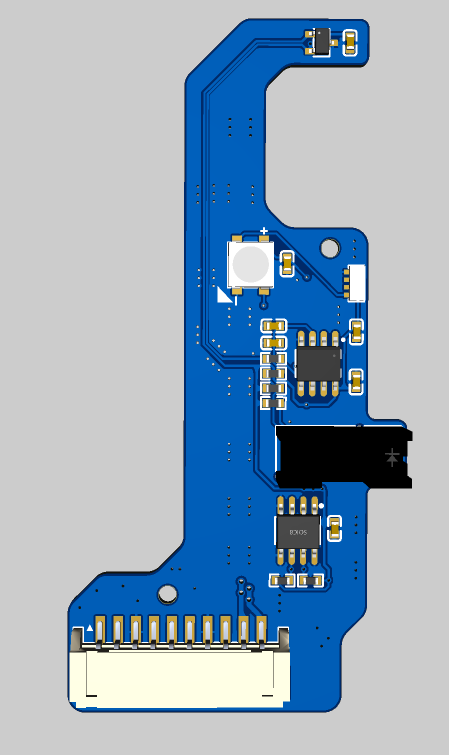

¶ Mainboard

All mainboard versions are universal and compatible with any version of the BMCU — they are fully interchangeable.

The newer official version, which includes additional protection circuits, is designed to reduce the risk of damage during hot-plugging or similar accidents (although hot-plugging is still not recommended). However, we’ve observed that this version may occasionally experience issues. Therefore, we recommend not soldering the SS54 diode located next to the 5050 LED in the upper right corner; instead, you may directly short it for better reliability.

Alternatively, you can also consider using @XC’s side-mounted Type-C mainboard, which has proven to be an excellent choice as well.

¶ Original version

¶ With Enhanced Security Patch

For Mainboard with Enhanced Security Patch

We have noticed that this mainboard may exhibit some abnormal behavior.

This could lead to unexpected reboots or even damage the 24V to 3.3V power conversion circuit.

Our preliminary findings suggest that the issue may originate from the SS54 diode located at position D4 in the upper-right corner of the board.

If you plan to produce this board, we recommend not soldering this diode. Instead, directly bridge the pads using copper wire, solder, or a resettable fuse.

For Mainboard with Enhanced Security Patch

The small diode next to the 75176 chip is modeled in the wrong orientation in the soldering aid, please refer to the silkscreen on the mainboard。

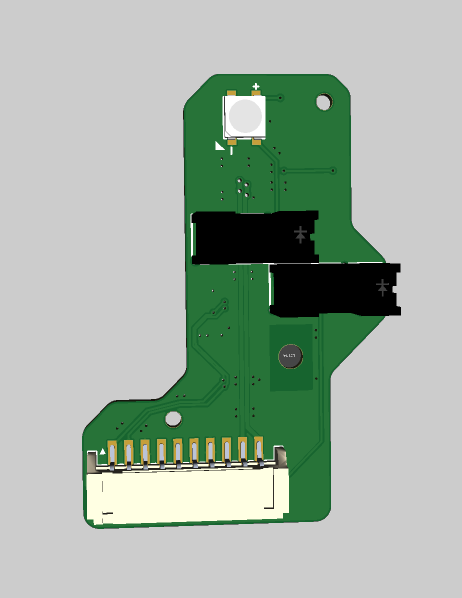

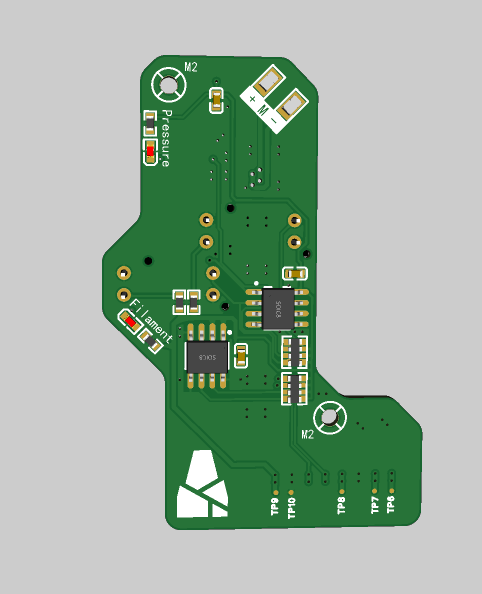

¶ Sub-board

¶ Original version - Dual photoelectric sensor

¶ Hall sensor version

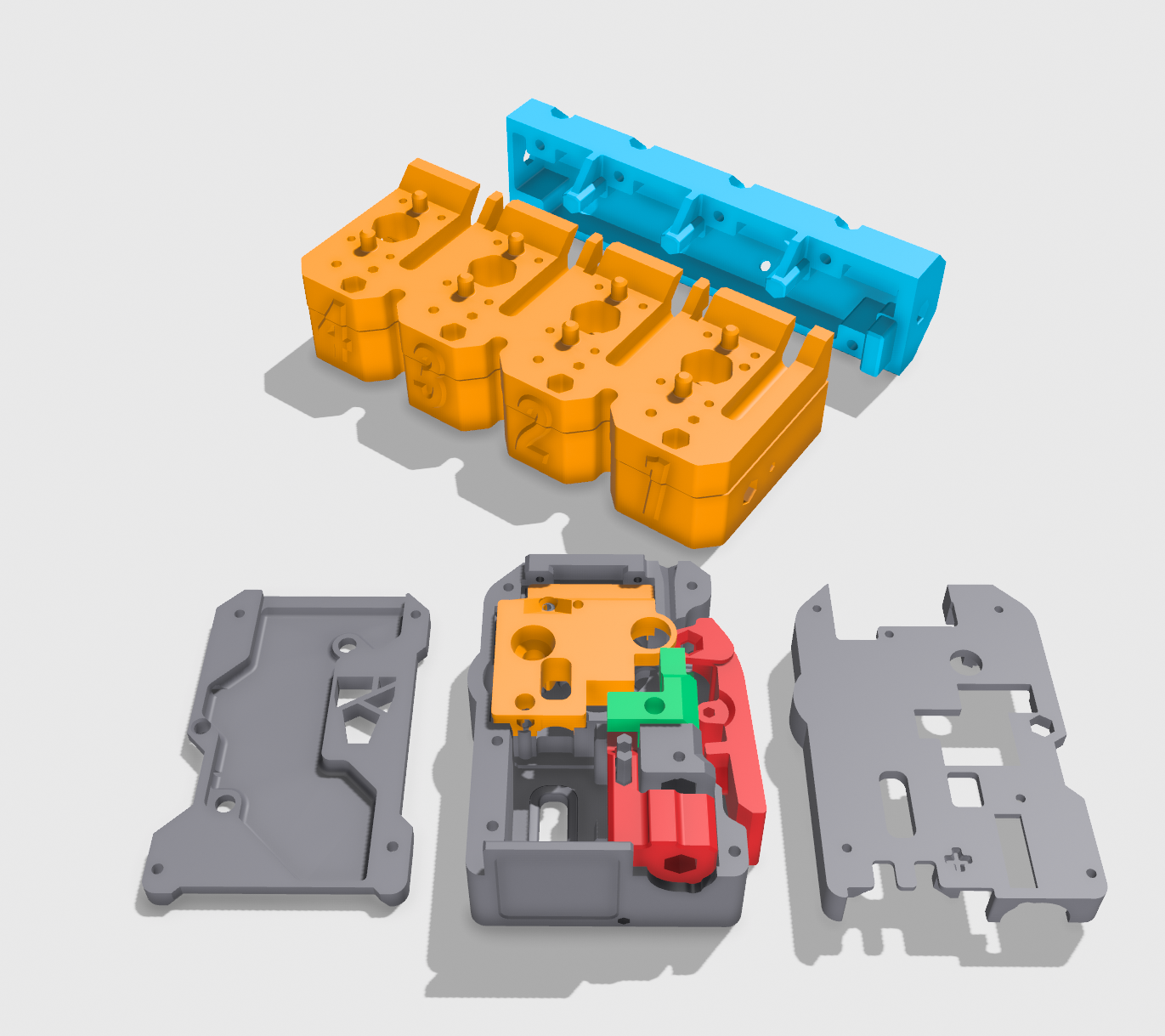

¶ BMCU-A

¶ 130 version

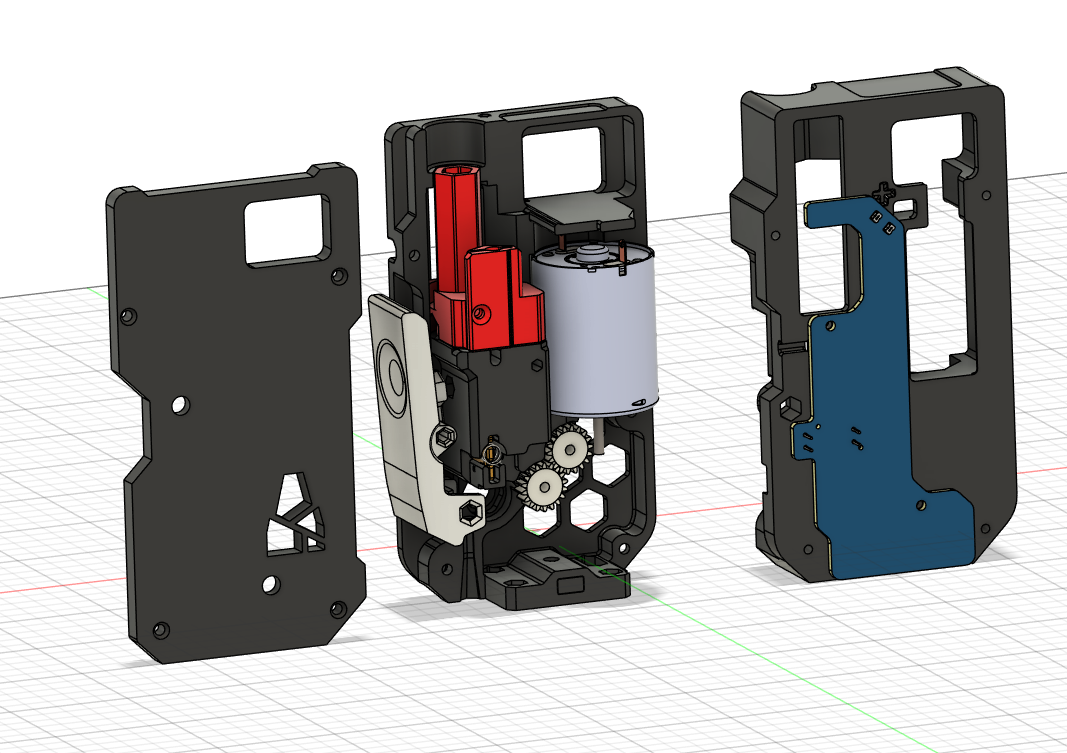

The model in this picture is the latest version (as of 25/02/2025) of the version 130 model, which in the extruder it uses a Split design and an adjustable photoelectric block (green part) to improve performance.

The original version 130, the most classic and earliest version of the BMCU from the author, has since undergone several iterative updates from the author and other developers to optimise its prints.

The problem with the 130 is that it has a ‘triangular plate clutch’ part, which lacks subsequent durability. It is also prone to various problems during assembly, such as idling gears. But for now, the 130 version is more stable with good fitment

update 31/03/2025 - Since the release of the clutch with springs, the installation and commissioning of the 130 version has been considerably reduced !

Version 130 is still well used today.

¶ 180 version

The 180 version is a variant of the 130 version, which uses the 180 motor and has been modified to fit this motor. The rest is still identical to the 130 version, with a triangle plate clutch structure.

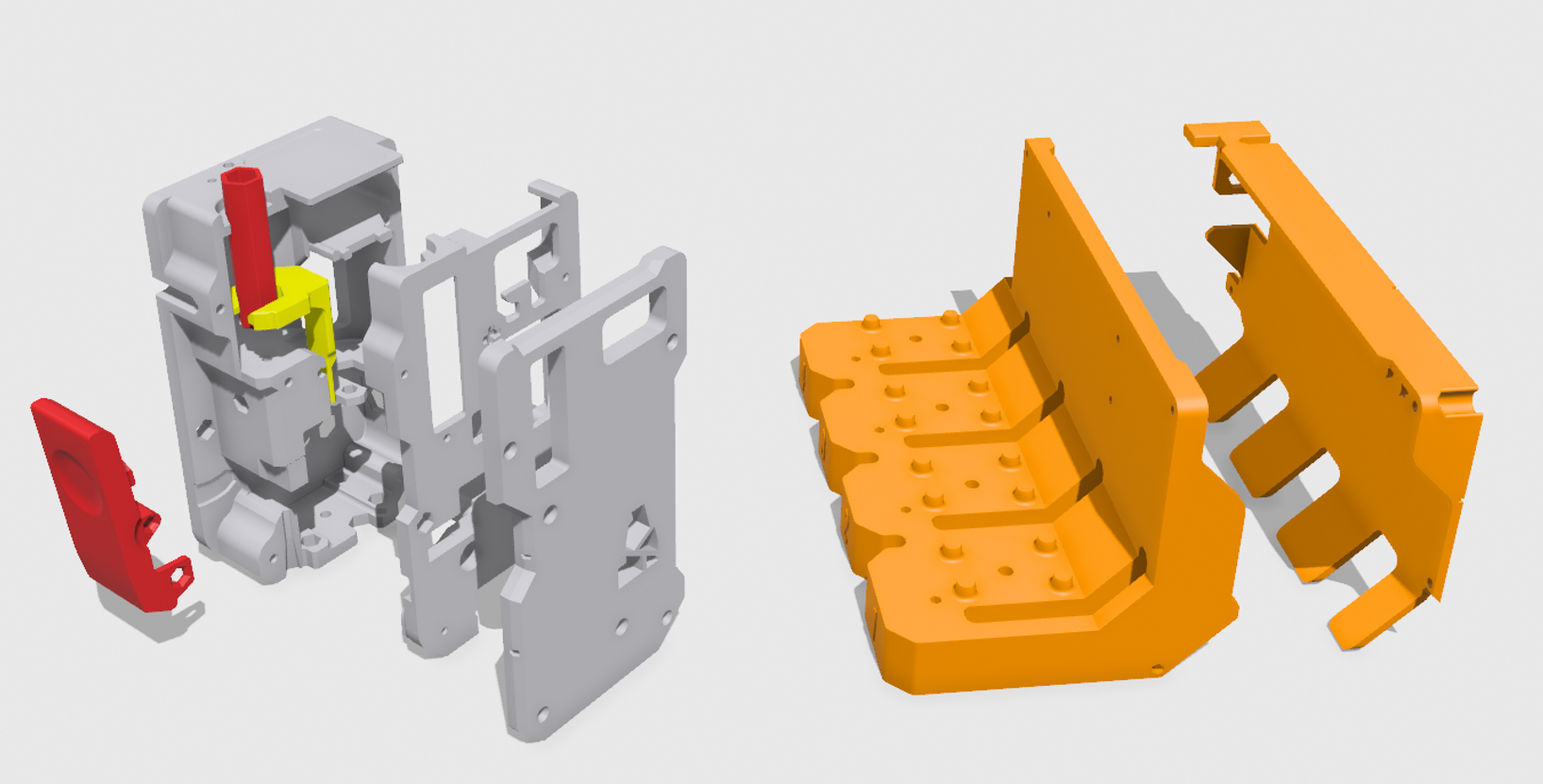

¶ BMCU-B

¶ v2.5 - with out steel ball

The 370 version means that its motor uses a 370 motor(24v 6000rpm) instead of the original FF-130sh motor

The 370 version will run theoretically faster, and improves on the original 130 version's potential problems of getting stuck at 99% and feed pressure.

The 370 version has a different noise aspect than the 130 version, and because the 370 motor has more torque, the BMG gears mesh better, and there is a certain amount of ‘filament chewing’.

Earlier versions of the 370 had the potential for five-pass explosion. The reason was that when the selected print speed was higher than 100%, the BMCU fed the material faster than the extruder, resulting in abnormal operation. The authors and developers have now improved the situation with a different structure of BMCU, but for now the 370 version is still in beta.

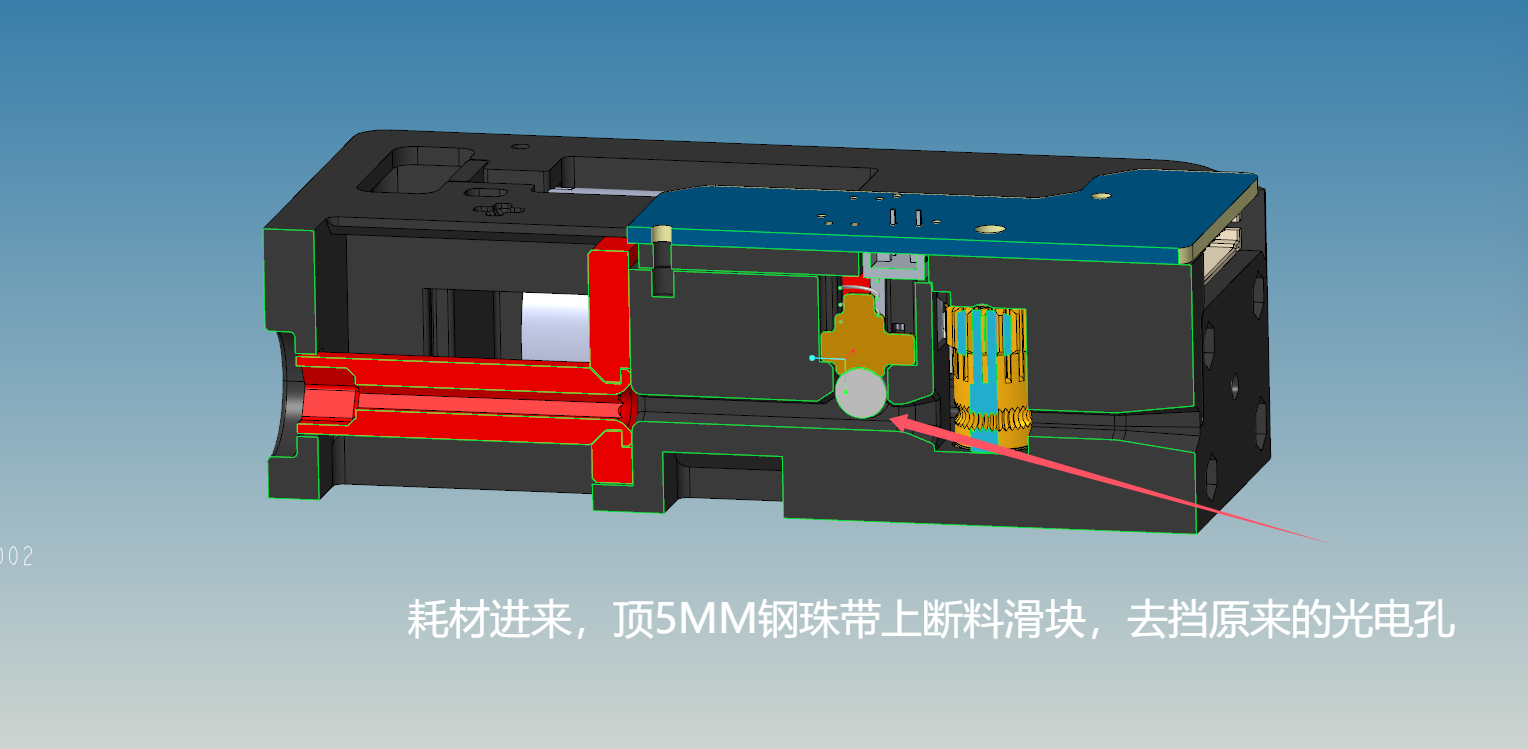

¶ v3.14 - with steel ball

The current steel ball version is an excellent version who better solves the problem of photoelectric sensors. It is usually recommended to assemble this version.

¶ BMCU-C

BMCU-C represents the latest generation of the BMCU. It is built upon the solid foundation of BMCU-B v3.14, incorporating significant improvements in both hardware and functionality.

BMCU-C uses a new subboard equipped with a Hall sensor. Unlike the one-way buffer mechanism in BMCU-B, BMCU-C introduces a bi-directional buffer system. This upgrade greatly reduces the risk of AMS Lite Hub ejection under pressure, a problem that occasionally occurred in previous designs.

BMCU-C also brings several new smart features, such as:

-

Material insertion on buffer head press

-

Material retraction when the buffer head is pulled out

-

Multi-BMCU setups on P-series printers and also can be used with AMS systems

If you're looking for the most stable, feature-rich, and future-ready BMCU experience, BMCU-C is the ultimate choice.

¶ BMCU-D

¶ Should I get a BMCU-A or BMCU-B or BMCU-C?

It is always recommended to assemble the BMCU-C directly. As of today (update date: 02/07/2025), there is no reason not to choose BMCU-C.

By choosing BMCU-C, you get more features and longer-term maintenance support.

-

BMCU-A: Unless you’re looking for a personal challenge.

-

BMCU-B: Although exceptionally well-designed, the author of BMCU, @4061N, will no longer release any firmware or enclosure updates for BMCU-B. However, since the source code is fully open, it might be a good starting point if you plan to develop your own AMS system.

-

BMCU-C: The best BMCU to date — there’s simply no reason not to go with it. However, the source code will remain closed for now. Please respect the author's decision.

-

BMCU-D (experimental): If you're a P-series user, choosing the D version could make sense although not neccesary. Note that as of the current update, it doesn’t support multiple BMCUs (as it's essentially a modified BMCU-A). More updates are planned in the future. Personally, I would only recommend this version to developers or hardcore enthusiasts.